Watergallon 333 x consistency where 333 is a rate of change factor. Areas mixing speed hygienic design ribbon blenders are.

Filter Presses Hoffland Environmental Inc 936 856 4515 Manufacturer Of Industrial Wastewater Treatment Systems

FAURE EQUIPEMENTS Filter presses Page 6 b Design and Operating principles Filter presses comprise a set of chamber plates covered by filter clothes and squeezed by a hydraulic cylinder between a stationary frame and a mobile supporting beam.

. Over the history of commercial businesses and municipalities utilizing filter presses for a multitude of applications two basic and reliable mathematical formulas have been developed to cover most situations. Designs exist which are over-performing ribbon blenders in some. Sludge quantity 112000 Ld 29540 gpd Water in lime at 10 solution 280 kgd 01 x 1 kgL 2800 Ld 740 gpd Water in polymer at 5 solution 112 kgd.

1800 gallonsday 3 cyclesday 600 gallonscycle. Ribbon mixers are very widespread in process industries for bulk. Slurry is semi-liquid mixture which is typically composed of fine.

However the gravity rate of drainage seems to under predict the dosages for optimum belt filter press performance. Download as PDF TXT or read online from Scribd. Filtering cycle will start with the filter press closed.

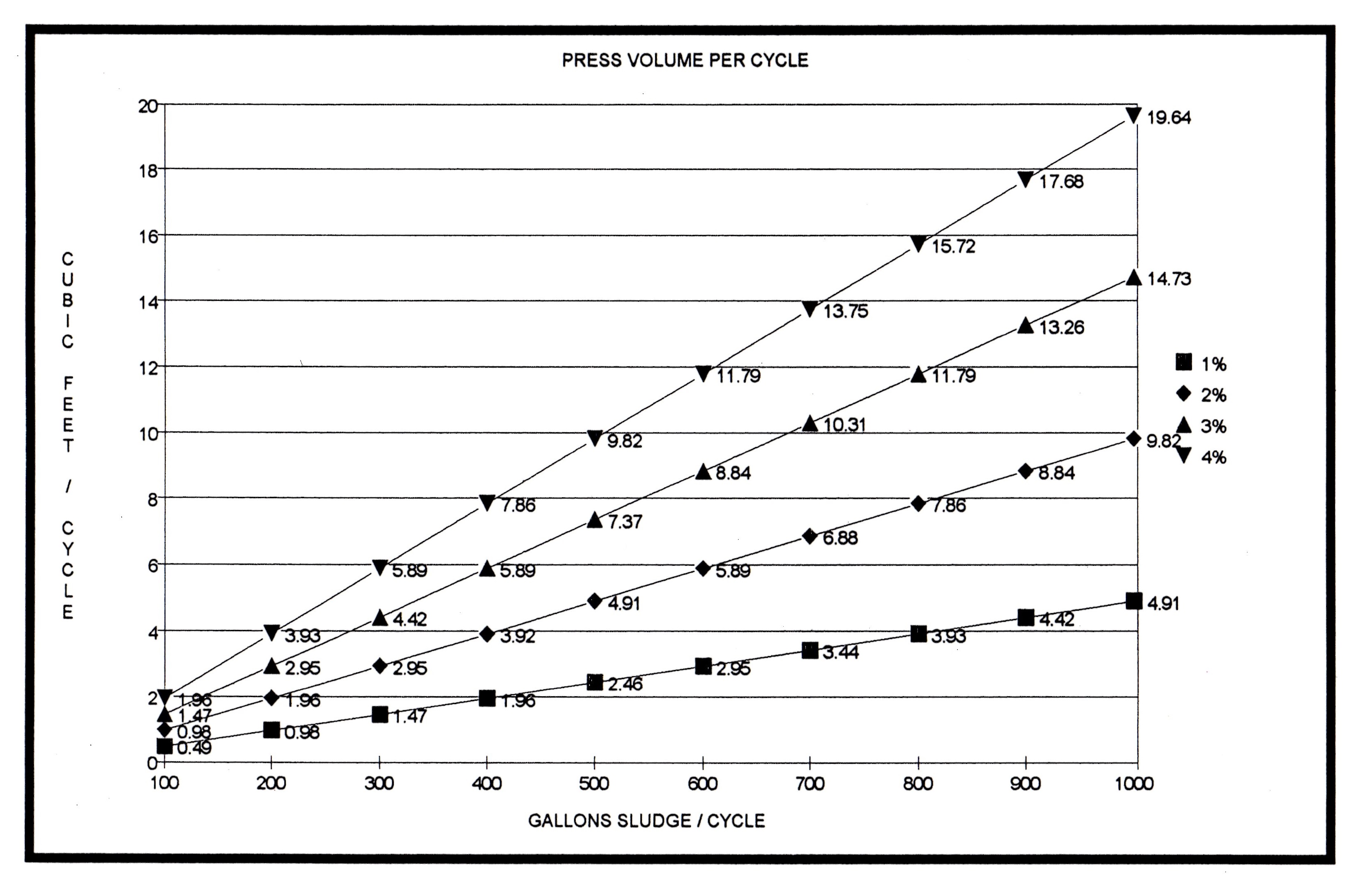

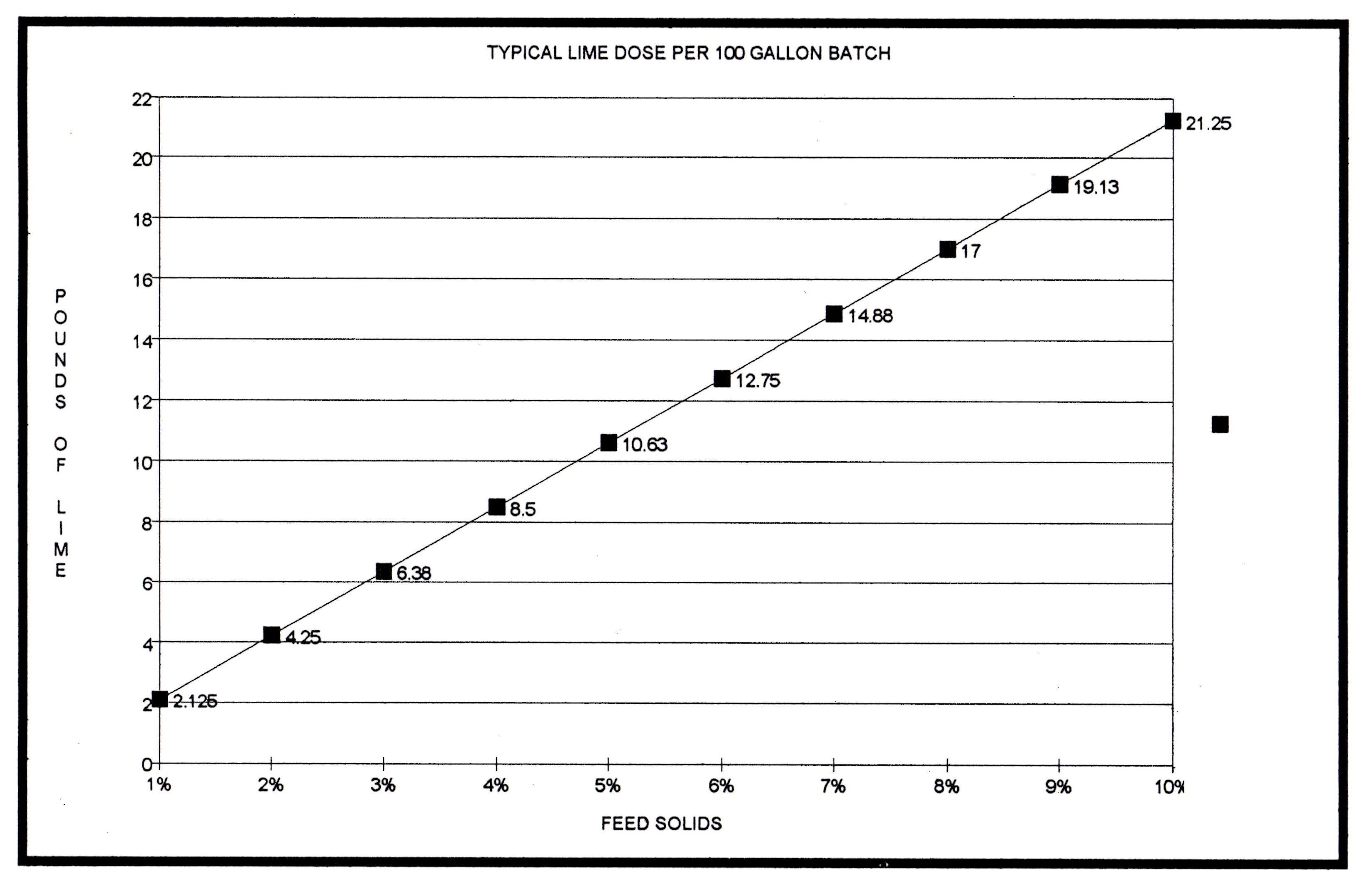

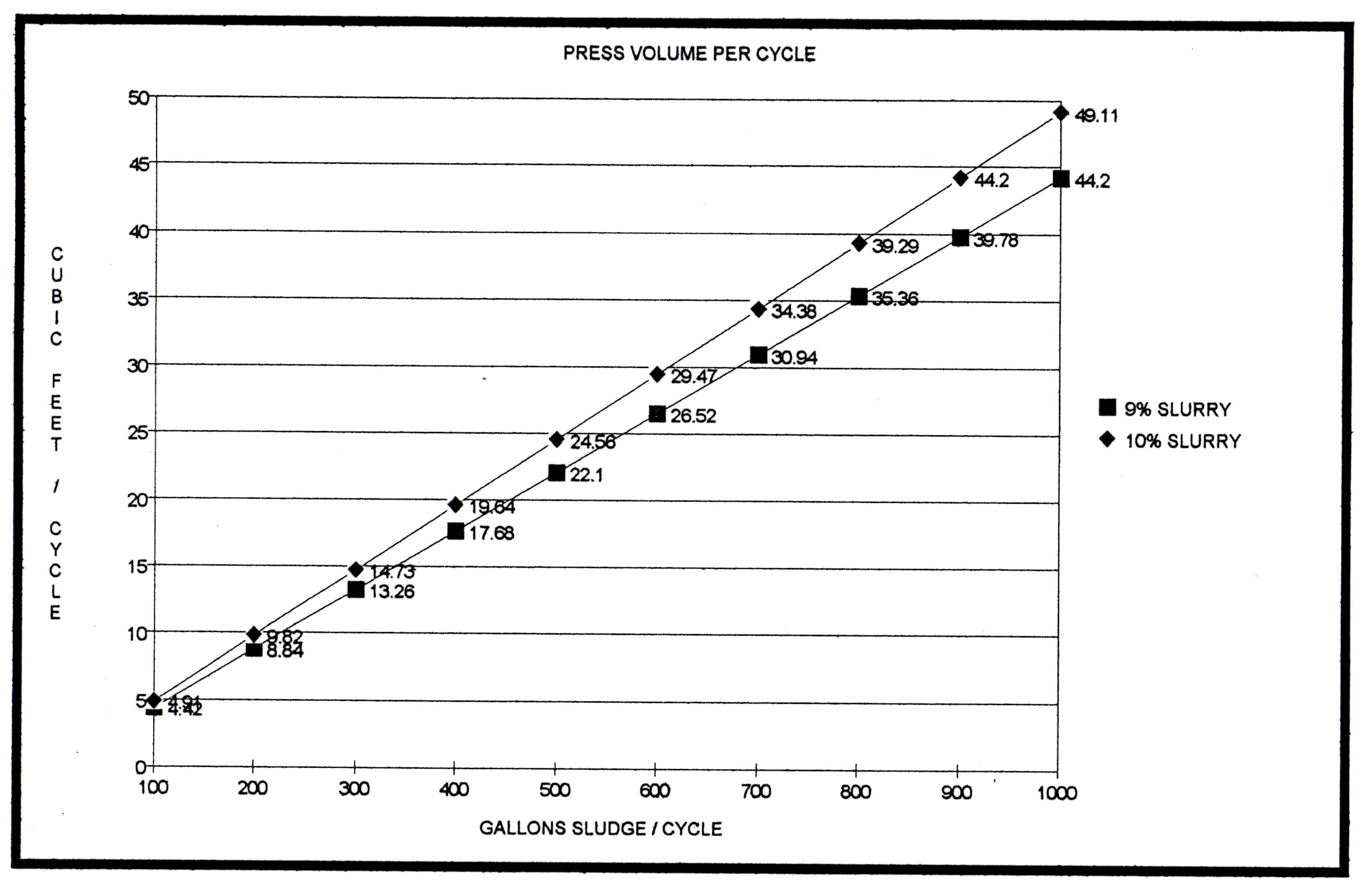

With this information we can estimate the filter press volume and chemical conditioning requirements. Calculate friction loss using Mannings formula as though it is flowing with water. This service will assist you in planning and sizing your filter press machine.

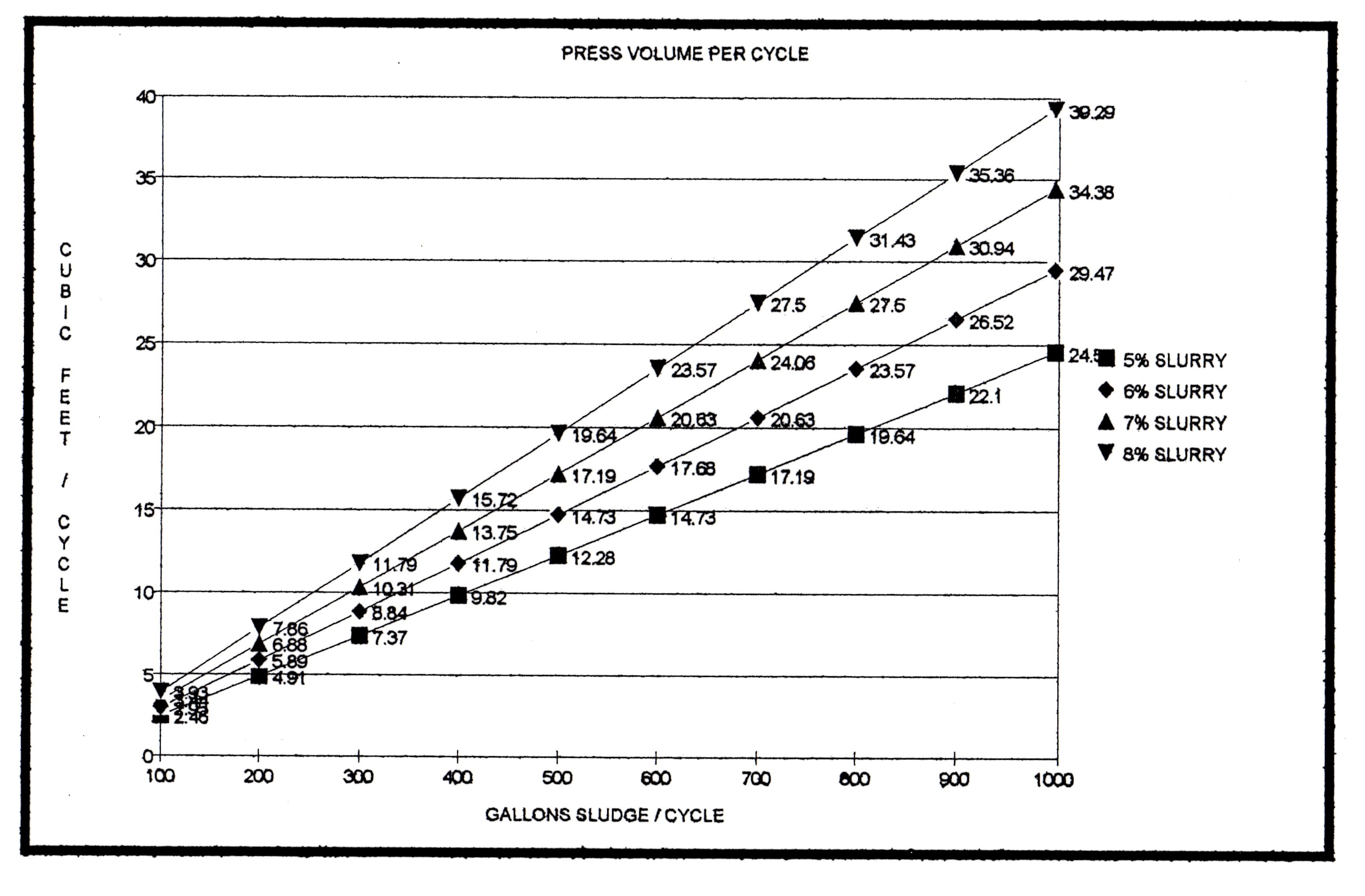

Now we can go to our press volume per cycle graph to determine the press volume. How to Determine the Size of Filter Press for your Project. F for digested sludge is 152 0041PP 0227P 6.

Of a belt filter press were the same. The plates determine a watertight volume in which is pumped the pressurized sludge. Flag for inappropriate content.

The initial phase of the filtering cycle starts with the closure of filter press. The first formula covers most standard slurries. Belt filter presses are used to remove water from liquid wastewater residuals and produce a non-liquid material referred to as cake Dewatering wastewater solids reduces the volume of residuals improves operation and reduces costs for subsequent storage processing transfer end use or disposal among other benefits.

Movable plate is triggered by hydraulic system and is moved closing the filter at the pressure needed for the work which is controlled with a pressure switch positioned in hydraulic circuit. What is a ribbon blender. In addition the total mixing energy G the shear and t the mixing time that represents the laboratory belt filter press was found to be approximately 45000.

Please note that this result is an estimated value based on solid-liquid separation. Belt Filter Presses Design Information Report. Calculation of the processing capacity of the belt-type thickening filter press 21 The first calculation method of the processing capacity of the belt-type filter press takes the thickness of the wet cake produced by the belt filter as the main calculation parameter and then calculates based on the calculated output of the wet cake The output feed volume ie.

For the press section the pressure P is calculated by the belt tension the press roll and the contact area of the filter belt and the concentration C0 into the press section is the concentration of the concentrated sludge 8 to 10 Ck is the final cake concentration 25 T ts T2 ts for the actual filter time press the filter belt and press roll contact length press the filter belt. The above multi-media filtration calculator calculates the diameter of a round multi-media filter MMF based on the filter bed speed as input. The second formula covers slurries composed of metal hydroxides which are often found in wastewater from.

CLOSURE OF FILTER PRESS. We now know that our customer will need a press with a capacity of approximately 24 cubic feet. Save Save Filter Press Sizing Calculations.

Under pressure slurry was pumped into filter press and dewatered the liquids. F for undigested sludge is 288 0176PP 0866P 5. 100 8 100 found this document useful 8 votes 4K views 2 pages.

For industrial water filtration purposes vertical filter bed speeds ideal service flows varying between 10 mh and 25 mh are used depending on the quality of the to be treated water. EPA United States Environmental Protection Agency Water Engineering Research Laboratory Cincinnati OH 45268 Office of Municipal Pollution Control Washington DC 20460 Research and Development EPA600M-86011 May 1 986 Design Information Report Belt Filter Presses The U. Consistency in is pounds mass of fiber contained in pounds mass of the mixture of fiber and water Weight of dry fiberweight of mixture of water fiber.

We will be pleased to support you with your detailed calculation of your dewatering plant. Still a very simple and robust solution to mix dry materials. The total quantity of conditioned sludge plus chemical solution to the filter presses follows.

This friction loss is multiplied by a friction compounding factor F as follows 3. Calculate the size of your chamber filter press with our online calculator. Calculations used in the design and incorporates the results of treatability studies where appropriate.

This attachment presents the assumptions and calculations. Requirements to Belt Filter Presses the dewatering pressure 45 30 15 Primary paper sludge Thin sludge 1-2 DS Digested sludge 3 DS Primary fresh sludge Difficult dewaterable sludge 12 18 24 Throughput m³h Throughput Belt width m 45 30 15 PETKUS Belt Filter Presses are suitable for a con-tinuous sludge dewatering process with maximum. Estimate the solids content in the sludge P.

The overall process flow diagram for the processing facility is presented in Sections 3641 and 3642 and shown on Contract Drawings P-2002 and P-2003. Filter press is a batch operation fixed volume equipment having different fixed processing capacity that separates solids and liquids using pressure filtration.

Filter Press Sizing Calculations Automatic Filter Press Filter Press Pumping Equipment

Pdf Filter Press Dayanand Patil Academia Edu

Filter Press Sizing Calculations Automatic Filter Press Filter Press Pumping Equipment

Filter Press Sizing Calculations Automatic Filter Press Filter Press Pumping Equipment

Filter Press Sizing Calculations Automatic Filter Press Filter Press Pumping Equipment

0 comments

Post a Comment